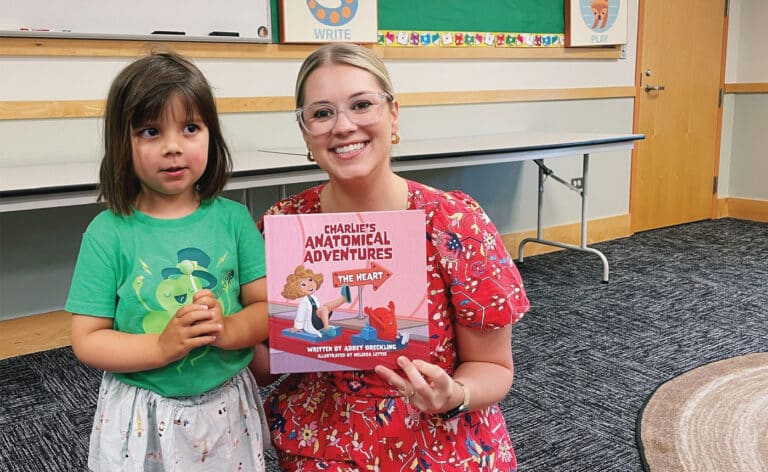

Pictured above: Students use the models to practice performing complicated minimally invasive procedures to repair rare birth defects. Photo courtesy of Northwestern University Feinberg School of Medicine.

By Kate Silver

On the counter sits a realistic leg, from the knee down, with a crimson gaping wound to the outer ankle. Nearby is a pair of white plaster hands, a silicone breast and a rib cage so very tiny that it could fit in one hand.

It feels a bit like I’ve walked onto the set of The Walking Dead. But in reality, this room—the Innovations Lab at Northwestern University Feinberg School of Medicine—illustrates the changing face of education in medicine, and much of that is thanks to 3D printing.

Each of the body parts in front of me was created with the goal of training medical students and doctors to heal patients. The tiny rib cage, which was created with a 3D printer, helps medical students and doctors learn how to perform complex surgeries on newborn babies. With a silicone arm, they practice inserting IVs. With the injured leg, they practice assessing and dressing wounds.

Katherine Barsness, MD, came up with the idea for the small rib cage (more on that in a bit). An associate professor of surgery and medical education at Northwestern University Feinberg School of Medicine and associate director of clinical and translational research in surgery with the Ann & Robert H. Lurie Children’s Hospital of Chicago’s Stanley Manne Children’s Research Institute, Barsness says that, today, this is the way that pediatric surgeons are being trained to be advanced minimally invasive surgeons. In the past, she says, doctors learned how to do surgery by actually doing the surgery—on living, breathing patients. Today, by performing simulated surgeries on realistic printed 3D organs, limbs and other parts, they’re far more practiced than in the past, even before setting foot in an operating room.

“There’s a learning curve for everything we do in life. And that learning curve has always been borne on the backs of patients,” Barsness says. “With advanced training models, that learning curve now is [taking place] in a simulated operating room, away from patients.”

And that’s something that could impact all of us.

3D Personalized Medicine

The idea of 3D printing in medicine can be hard to get your head around at first. But think about it like this: Dentists have been using 3D printers to create crowns for a long time. Boiled down, it’s simply creating a unique part, tailored to you, on demand.

In medicine, 3D printing is used to create prosthetic limbs, stents, hearing aids, knee implants, joints, plastic and titanium replacements for bones, and the list goes on. In 2011, Barsness got the idea of using 3D printed parts for training. She was touring the simulation lab and she saw a small, plastic rib cage that had been created on a 3D printer. It gave her an idea: What if the lab could create a simulated lifelike newborn’s rib cage that doctors could use for practicing procedures? If that were possible, it would be a huge improvement on what students were currently using to practice surgery: pigs.

“We’d always [used] what I [called] a toddler pig. It was a 22-pound pig. As you can guess, newborn babies are not 22 pounds,” Barsness says. “My initial goal was to create something that would provide a better teaching experience for the surgical fellows in Chicago.”

Lauren Davis, a member of the Innovations Lab at Northwestern Simulation, began working on the rib prototype in 2011. Over nine months, she created a blueprint for the rib cage using 3D design software, radiology scans, measurements and angles of an average newborn chest and abdominal cavities.

It was still under development when Ellie O’Brien, Innovations’ design engineer in the Department of Medical Education at Feinberg, began working at the lab in 2012.

During an interview at the lab, O’Brien says one challenge in designing the rib cage was finding the right printing material to make it realistic. Plastic ribs, the designer learned, could crack too easily when adjusting the laparoscopic tools. Using rubber, the staff at the lab sought to create a more true-to-life texture that had a similar pliability to a newborn’s soft bones.

The result is what students and doctors practice on in the lab today: a rib cage made of a hard plastic shell, with rubber filling each rib, making them flexible. But the rib cage, itself, is just the beginning. It’s then covered in silicone skin and prepped for a procedure. When students are operating, silicone organs are placed inside. When more practiced surgeons are operating, bovine tissue sculpted to mimic different congenital defects is placed within.

It’s been an enormous success: Every pediatric surgery fellow in the United States and Canada now comes to this Chicago lab to work on the models each year, and these models are also being used globally. Barsness says she never had any inkling it would take off the way it did. “Hopefully, we truly are helping children, not just here in Chicago, not just in the state of Illinois, but throughout the world,” she says.

In the lab, O’Brien makes many of the models using data from CT scans and MRIs and is able to create an exact replica of a human body part. She prints it here, in the lab, or through its collaborator, McCormick School of Engineering and Applied Science. The printer works by layering extremely thin strata of a substance—100 layers measures just one centimeter—of hard plaster, plastic, rubber or other materials.

Recently, when a cardiologist at Lurie Children’s Hospital needed additional insights into the heart of a young child, he called the Innovations Lab and asked O’Brien for help. The physician wasn’t able to get all of the information he needed from a CT scan, so he asked O’Brien to build a 3D model based on the scan. “They sent me the data. I edited it, 3D printed it and was able to [provide him a replica of] this little girl’s heart,” O’Brien says.

A Model Operation

For nearly 15 years, Henry Finn, MD, medical director of the Chicago Center for Orthopedics at Weiss Memorial Hospital, chairman of surgery at Weiss and professor of orthopedic surgery at the University of Chicago, has been relying on 3D models made from CT scans in his practice.

As a specialist in hip and knee replacement surgery, with additional expertise in revisional surgery of the hip and knee, Finn sees many patients who have lost a massive amount of their bone stock through previous surgeries, trauma, tumors, congenital deformities, and a variety of illnesses or drugs that result in bone damage. When they come to him, most are in constant pain. Often, their hips or knees are in such disrepair that one leg is inches shorter than the other, or the hip socket is so deficient that the femur is poking into the pelvis.

When there’s been extensive loss of bone and soft tissues, he says it may be almost impossible to fix or attach new implants needed to construct the hip or knee, and he is often the last hope for patients, who frequently travel long distances for his expertise. By creating 3D models, he goes into surgery prepared for what he’s going to find, no matter how complicated it is.

“Holding this [a 3D model] in your hand before surgery allows us to preplan the surgery as though we’re actually doing it, by touching and holding these complex anatomical defects that are normally surrounded with muscles, arteries, skin, fat and are hard to see in the operating room,” Finn says. “Rather than conventional X-rays or CT scans, we have this 3D structure, so we can clearly define the defects and practice the surgery and go into this rehearsed.”

Lucille Bryson, 56, traveled from her home in Highland, Ind., for a hip revision in 2014. This was her second surgery with Finn, who first replaced her hip in 2010, after she developed a condition called avascular necrosis, where the ball of her hip socket lost its blood supply, collapsed and eroded through her pelvis. Soon after that surgery, a revision was needed because of early failure related to her weakened bones caused by medications.

“I walked around with a loose hip for about a year and a half,” says Bryson, during a phone call from her Indiana home. She says one leg was quite a bit shorter than the other, and she took pain medicine regularly in order to function.

Finn said the challenge with Bryson was, in both surgeries, her bones. “Her bone is not only deficient, it’s also structurally very weak,” Finn says. “If bone would be the structure of an oak broom handle, her bone is like balsa wood.”

Finn told Bryson that he was going to build a 3D model—i.e. a plastic pelvis—using her scans, in order to practice the surgery and prepare. With the help of the model, he could plan the hip revision procedure step by step, rebuilding her socket. Inside the plastic pelvis, he could practice placing something called a cup-cage construct, which is a metal device that connects the lower and upper parts of the pelvis. By the time the actual surgery came around, he had studied every aspect of her pelvis, and he was ready.

For Bryson, that brought peace of mind. “I had all the confidence in Dr. Finn, because I knew he knew what he was doing,” she says.

The surgery was a success. “When I came out, I felt better than when I went in,” Bryson says. Today, more than 15 months later, she says her hip is still doing well.

Finn says that 3D models have completely changed the way physicians navigate. “Using an X-ray to predict what we’re going to find in the operating room, compared to using a 3D model, would be like using an old-fashioned road map versus using navigation systems that are in cars today,” he says.

The surgeon says he has great hopes for the impact of 3D printing in the future. “It’s a game changer,” Finn says.

Back at the Innovations Lab, Ellie O’Brien agrees. “There’s just tons and tons and tons of applications,” she says. “I feel like we’re just breaking the surface here.”

Barsness says that even beyond 3D printing, simulation-based education will bring great changes to healthcare in the future. “It provides the basis for mastery learning outside of patient care,” Barsness says. “So you master techniques, you master the situations, you master decision making in realistic, immersive scenarios, but you actually master all of it ahead of time. And then you use those skills with real patients.”